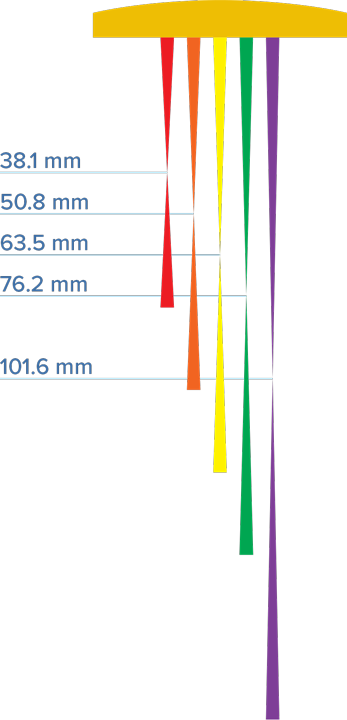

We stock several lens options at Rabbit Laser USA, each designed to cater to specific needs and purposes within laser cutting and engraving projects::

- 38.1mm (1.5 inches): This lens is best used for high-precision engraving. Its shorter focal length allows for a tighter focus, making it ideal for intricate details in fine artwork or precise text. It's perfect for projects that demand sharp, fine lines and intricate patterns.

- 50.8mm (2 inches) - Default Lens: As the standard lens equipped on all our machines, it offers versatility for both cutting and engraving. This lens strikes a balance between detail and efficiency, making it suitable for a broad range of applications, from moderate engraving to general cutting tasks.

- 63.5mm (2.5 inches): Excelling in projects with slight curves or uneven surfaces, this lens is particularly useful for engraving tumblers and other cylindrical objects. The increased focal length provides a greater depth of focus, which compensates for surface irregularities and ensures consistent engraving quality.

- 76.2mm (3 inches) and 101.6mm (4 inches): These lenses are geared towards cutting through thicker materials. Their longer focal lengths allow the laser to penetrate deeper, making them suitable for tasks requiring substantial material removal or thicker cuts. They are ideal for large-scale or thick material projects where depth and cutting power are necessary.

By understanding the specific purposes of each lens, you can better match your lens choice to your project's needs, enhancing both the efficiency and quality of your work. This targeted approach helps ensure that your machine operates at its best, delivering optimal results tailored to each unique task.