Crafting Precision: Merging 3D Printing and Laser Tech

At Rabbit Laser USA, innovation isn't just a buzzword—it's the cornerstone of our operations. By weaving together the capabilities of 3D printing and laser cutting, we craft solutions that not only meet but exceed the expectations of our diverse clientele. This blog explores the transformative impact these technologies have on our production processes, highlighting our commitment to precision and ingenuity.

How 3D Printing and Laser Cutting

Complement Each Other

At the heart of modern fabrication, 3D printing and laser cutting serve as foundational technologies that synergize beautifully. 3D printing allows for the swift creation of complex, tailored parts, offering expansive design flexibility. Conversely, laser cutting provides the meticulous accuracy and speed essential for cutting and engraving a variety of materials. Together, these technologies address multifaceted challenges, delivering products that are both innovative and precise.

Innovative Applications at Rabbit Laser USA

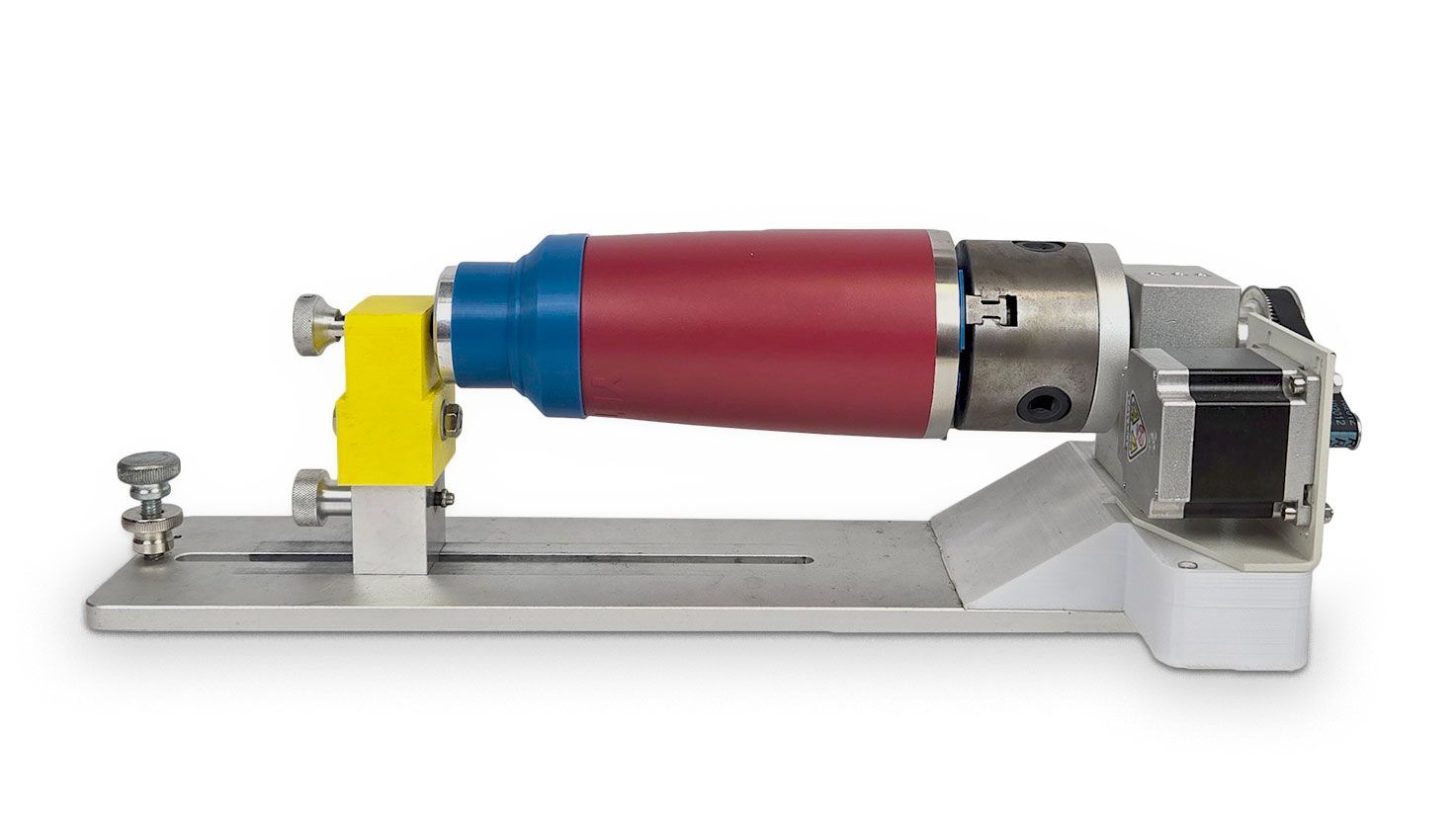

- Customized Attachments for Chuck Rotary: Leveraging 3D printing, we develop specialized attachments for our chuck rotary, such as risers, tumbler size adapters, and pet bowl adapters. These bespoke solutions enhance the adaptability of our laser machines, catering to an array of project demands and material types.

- Efficient Funnels for Chillers: Our custom-designed 3D printed funnels significantly optimize the functionality of our chillers, simplifying maintenance and boosting operational efficiency—a testament to our pursuit of excellence in every aspect of our work.

- Precision Enhancements for FSL Muse: Our in-house team crafts crucial upgrades like controller pad housings and lens focus tools for the FSL Muse machines. These enhancements are engineered to heighten usability and accuracy, epitomizing our dedication to enhancing machine performance.

- Jigs and Tools for Enhanced Laser Operations: Through 3D printing, we also fabricate custom jigs and tools that streamline and refine our laser cutting and engraving processes. These innovations are vital for maintaining high precision and consistency, ensuring premium quality in all our projects.

Guide for Makers and Businesses

Integrating 3D printing and laser cutting into your manufacturing process is more than just an upgrade; it's a transformation that can significantly enhance both the quality and efficiency of your outputs. By pinpointing specific aspects of your production that could benefit from these technologies, such as areas requiring enhanced precision or customization, you can harness their potential to address your unique challenges. At Rabbit Laser USA, we are not just practitioners but also passionate educators in this field, ready to share our knowledge and assist you in navigating the advanced manufacturing landscape.

Moving Forward Together

As we continue to innovate at the forefront of digital fabrication, Rabbit Laser USA remains committed to refining and advancing the integration of 3D printing and laser cutting technologies. Our goal is not only to meet the current needs of our clients but also to anticipate future demands, ensuring we provide solutions that are not just effective but revolutionary. If you’re looking to elevate your production capabilities, don’t hesitate to reach out. Discover how our expertise and cutting-edge technology can transform your projects and lead you towards a more innovative future. 🐰