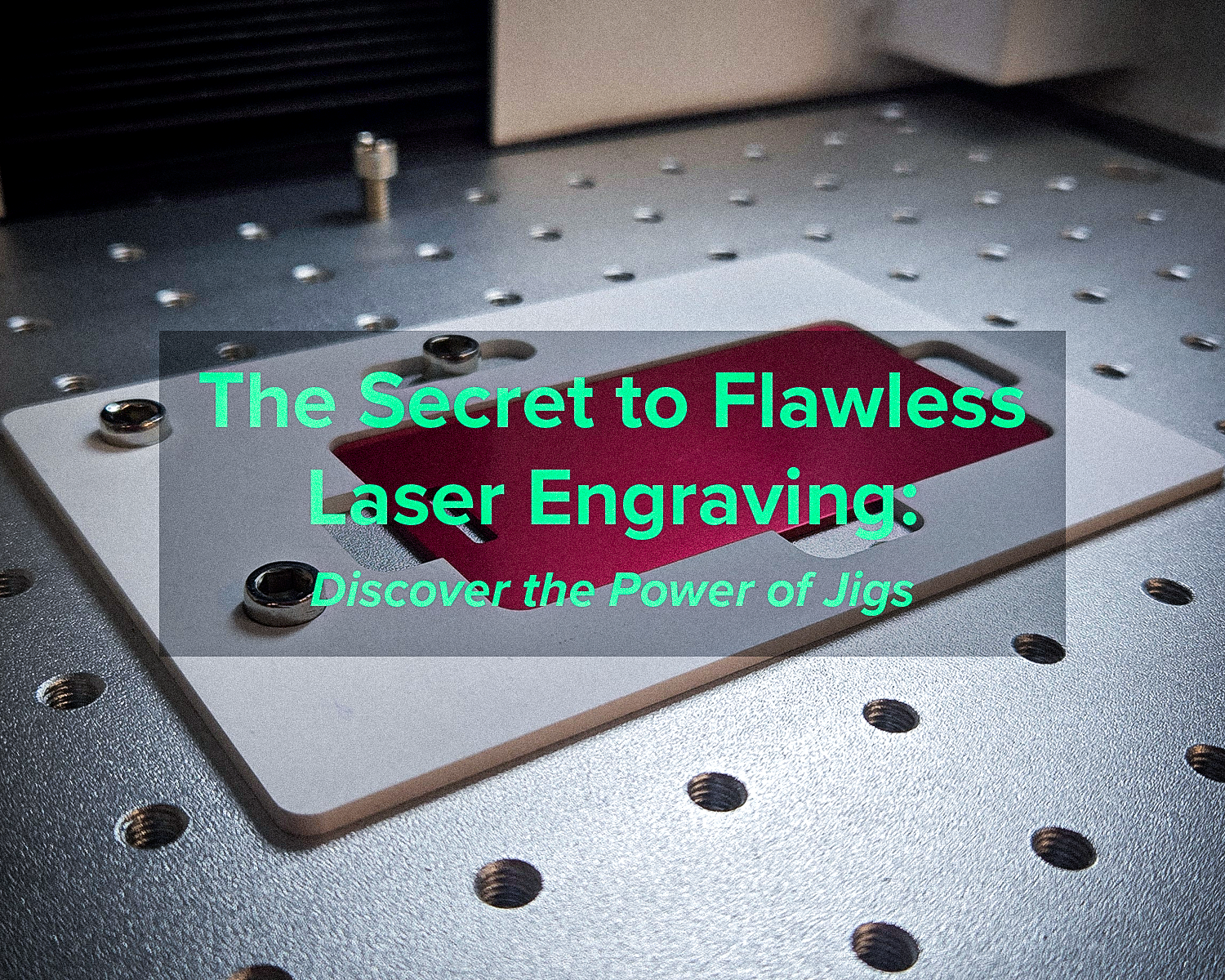

The Secret to Flawless Laser Engraving: Discover the Power of Jigs

Laser engraving is a precise art, one that transforms ordinary materials into beautifully etched items with the power of light. But even the most advanced laser technology can fall short without the right support tools. Among these, jigs are paramount for achieving flawless results. But what makes jigs so essential in laser engraving? Let’s dive into the intricacies of these tools and their profound impact on the engraving process.

Understanding Laser Engraving

Laser engraving is a technique that uses lasers to engrave an object. This method offers several benefits over traditional engraving techniques, including precision, versatility, and speed. Commonly engraved materials include metals, plastics, glass, and even wood.

What Are Jigs?

In the realm of laser engraving, a jig is a custom-made tool that holds and stabilizes materials during the engraving process. Jigs ensure that each piece of material is positioned accurately and consistently, which is crucial for achieving high-quality engravings.

The Importance of Jigs in Laser Engraving

Jigs are not just about holding materials in place; they ensure precision and repeatability, which are crucial for high-quality outcomes. They also enhance safety by securing materials properly, preventing slips or movements that could lead to accidents.

Types of Jigs for Laser Engraving

Jigs come in various forms, each suited to different tasks. Adjustable jigs offer versatility for different material sizes, while custom jigs are tailored for specific projects. Magnetic and vacuum jigs provide strong holds without physical clamps, which is ideal for delicate materials.

Designing Effective Jigs

The best jigs are those designed with intention. Material choice for the jig itself can vary from metals for durability to plastics for reduced risk of scratching workpieces. Computer-aided design (CAD) tools are instrumental in creating precise and functional jig designs.

Setting Up Your Laser Engraver with Jigs

Setting up a laser engraver with jigs involves careful alignment and regular testing. Proper setup not only achieves better results but also reduces the risk of errors and material waste.

Purchasing or Creating Your Own Jigs

Whether you choose to buy pre-made jigs or craft your own, there are plenty of options available. Numerous resources also offer guidance on DIY jig projects, catering to those who prefer a hands-on approach.

Expert Tips for Optimal Engraving

When it comes to laser engraving, the quality of the final product is largely influenced by technique and preparation. Experts in the field offer a wealth of knowledge that can help both novices and seasoned professionals enhance their engraving skills. Here are some detailed tips to help you optimize your engraving projects using jigs:

- Choose the Right Jig Material: The material of the jig can significantly affect the outcome of your engraving. For delicate or easily scratched materials, using softer jig materials like certain plastics or rubber can prevent damage during the engraving process. For heavier or more abrasive materials, sturdier jigs made from metal or durable composites are recommended.

- Precise Jig Positioning: Accuracy in positioning your jig is crucial. Ensure that the jig aligns perfectly with the laser engraver’s focus point. Misalignment can lead to uneven engraving depth and blurry details. Use calibration tools and software features available in your laser engraver to achieve precise alignment.

- Regular Testing and Adjustments: Before embarking on a large batch of products, perform tests on similar materials to ensure everything is set up correctly. Adjust the jig and laser settings based on the test results to avoid costly mistakes on actual projects.

- Maintain a Clean Work Environment: Keep the area around your laser engraver clean and free from dust and debris. Excess particles can interfere with the accuracy of the laser beam and the stability of the jig placement, leading to flawed engravings.

- Control the Laser's Power and Speed: Adjust the laser's power and speed settings according to the material being engraved. Different materials absorb and react to the laser beam differently. For instance, softer materials may need a lower power setting to avoid burning, while harder materials might require more power to achieve a clear engraving.

- Use Multi-layered Jig Strategies for Complex Projects: For projects that involve engraving at different depths or on varied material types, consider using multi-layered jigs. These can allow you to set up several layers of material or adjust the height of the material in relation to the laser, enabling more complex and detailed designs.

- Leverage Software for Optimization: Utilize the laser engraver's software to optimize the placement and path of the laser. Advanced software can help you minimize travel time between engraving points, which speeds up the process and reduces the chance of error.

- Ensure Proper Ventilation: Proper ventilation is crucial when using laser engravers, as the process can produce fumes and smoke, especially when working with plastics or coated materials. Effective ventilation ensures a safer working environment and prevents build-up that could interfere with the laser's operation.

- Stay Updated on New Techniques and Materials: The field of laser engraving is constantly evolving, with new materials and techniques being developed. Stay informed about industry trends and updates by participating in forums, attending workshops, and reading recent publications.

- Customization Tips: Don't hesitate to customize the design and functionality of your jigs. If standard jigs do not meet the specific needs of your project, consider creating a custom jig that can accommodate unique sizes, shapes, or materials. This can lead to better engraving quality and more efficient processes.

By following these expert tips, you can significantly improve the precision, efficiency, and safety of your laser engraving projects, making the most out of your jigs and equipment.

Conclusion

Jigs are indispensable tools in the laser engraving process, ensuring precision, efficiency, and safety. Whether you are a seasoned professional or a newcomer to the craft, understanding and utilizing jigs can elevate your work to new heights. 🐰